Tungsten carbide, or cemented carbide, is one of the hardest alloys that have a wide range of applications, such as mining, construction, oil and gas, machine tools, cutting tools, wear parts, etc. Compared to steel, tungsten carbide is much harder and has a longer life time. When you need a metal that is harder than steel and more resistant to wear and impact, tungsten carbide can definitely meet your requirements. Although diamond is even harder than carbide, it is not an affordable alternative.

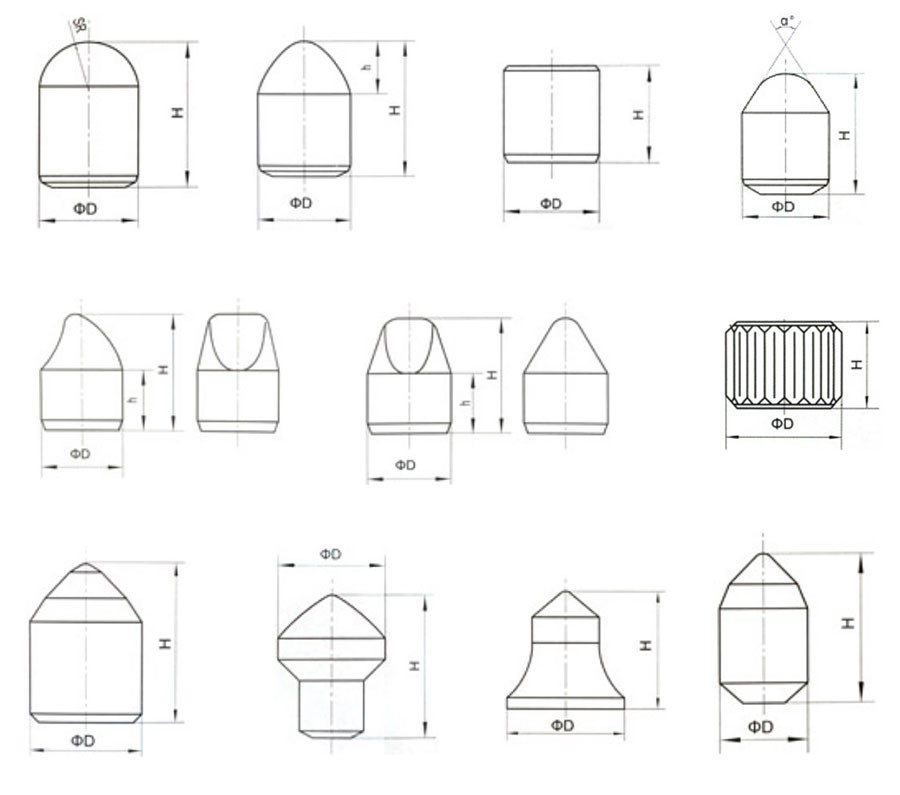

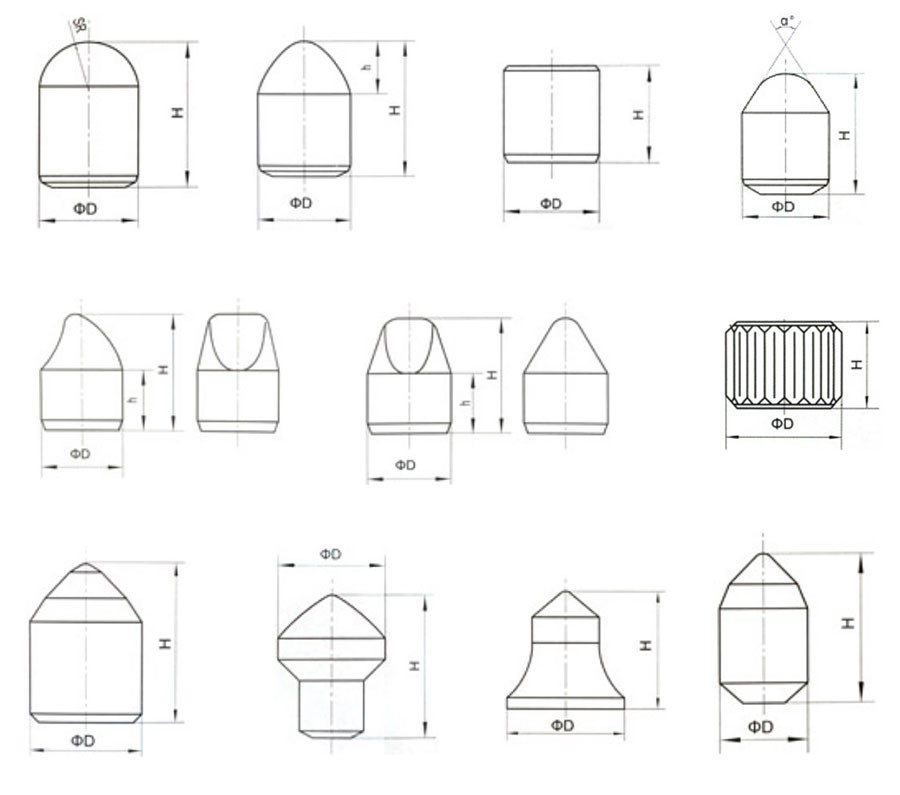

Tungsten carbide buttons can also be called tungsten carbide cutters, tungsten carbide inserts, cemented carbide buttons, or tungsten carbide tips. They are popular in oilfields, mining fields, and construction. Even for mining applications, the tungsten carbide buttons can be classified for different applications. Some are for tunneling, some are for cutting rocks, and some are for cutting minerals. Tungsten carbide buttons also developed several shapes, such as conical buttons, ball buttons, and spoon buttons. In this article, the brief characteristics and application of tungsten carbide buttons will be mentioned.

Tungsten carbide buttons

Tungsten carbide buttons can be named by what kind of shape or by their application. For different shapes, they can be categorized into conical buttons, ball buttons, parabolic buttons, wedge buttons, wedge buttons, and spoon buttons. For different applications, they can be divided into many types, such as rod digging buttons, oil field drill bits buttons, HPGR grinding buttons, and so on.

Tungsten carbide conical buttons

Tungsten carbide conical buttons have a sharper button profile, which can make them easy to invade the rock layer under the same working conditions. They can also excavate faster. This sharp head can be their advantages and disadvantages at the same time. They can improve the working efficiency but the sharp head is easy to wear.

Tungsten carbide ball buttons

Tungsten carbide ball buttons

Tungsten carbide ball buttons have a duller head than tungsten carbide conical buttons. So they are not easy to wear as the tungsten carbide conical buttons.

Tungsten carbide wedge buttons

Tungsten carbide wedge buttons

The shape of carbide wedge buttons is special and suitable for DTH drills. They have better wear resistance, longer service life, and can improve working efficiency.

Tungsten carbide spoon buttons

Tungsten carbide spoon buttons

Tungsten carbide spoon buttons have heads that look like spoons. They are mainly used to insert roller cones and drill rocks.

Tungsten carbide road digging buttons

Tungsten carbide road digging buttons

Tungsten carbide road digging buttons can be used on pavement milling machines and the equipment for concrete pavement maintenance and construction. They can also be used for the excavation and renovation of highways, urban roads, airports, and freight yards.

As an ISO-certified supplier,

ZHUZHOU HONGTONG has been dedicated to tungsten carbide button manufacturing for more than 20 years. We use high quality powders to guarantee tungsten carbide buttons’ quality at the source. The HIP sintering process can enhance mechanical properties and workability. Our advanced in-house facilities for quality inspection ensure all the carbide buttons’ quality before shipment.

Carbide buttons with varied sizes and grades are available and we also offer customization services.