Tungsten cemented carbide rollers (also called tungsten carbide roll collar) refers to the roll made from tungsten carbide and cobalt by powder metallurgy. Tungsten carbide rollers are available in both integral and combined versions. They have excellent performance, stable quality, high processing precision, good wear resistance, and high impact resistance.

With the increasingly fierce competition in the quality and price of steel products, steel companies are constantly updating their equipment technology to continuously increase the rolling speed of rolling mills. At the same time, how to reduce the rolling mill downtime and further improve the effective operation rate of rolling mills? It has become an important topic for rolling steel engineers. The use of roll materials with higher rolling life is one of the important means to achieve this goal.

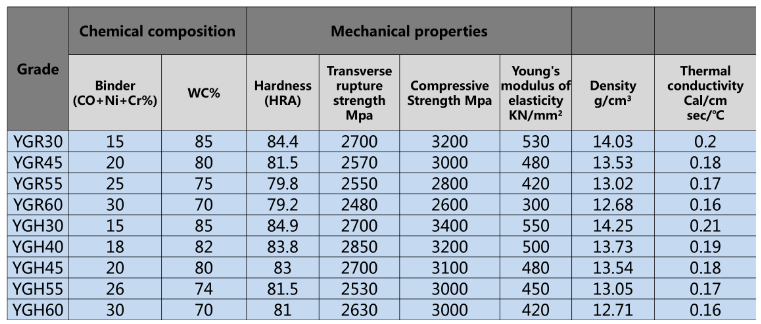

Due to its good wear resistance, high-temperature red hardness, thermal fatigue resistance, and high strength cemented carbide rolls have been widely used in the production of wire rods, rebars and seamless steel tubes, which greatly improved the work efficiency of the rolling mill. A variety of different grades of carbide rings have been developed based on the differences in the working conditions of the different racks and rolls.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.