Tungsten carbide rolls application:

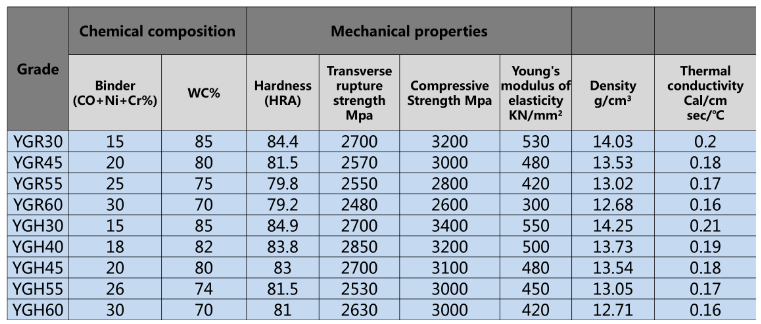

1. YGR30: Good toughness, wear resistance, corrosion resistance and thermal crack resistance. Used in most stands of the finishing mills and in the rear stands of common mils.

2. YGR40: Good toughness and thermal crack resistance, good for general purposes. Used in most stands of the finishing mills and in the rear stands of common mils.

3. YGR55: Good impact resistance. Used in the stands of pre-finishing rolling mills for hot rolling rebars and they can be machined with turning and milling.

4. YGR60: Good impact resistance. Used for hot rolling rebars and in the first and second stands of pre-finishing rolling mills and they can be machined with turning and milling.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.