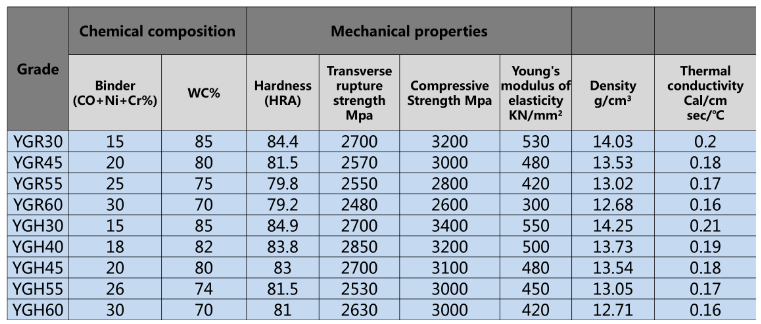

Tungsten cemented carbide roller ring is a kind of metallurgical tool which consists of tungsten carbide and cobalt with high hardness and wear resistance. There are ideal for use in applications where strength, durability and longevity are factors. The performance of the tungsten carbide roller is related to the content of the bonding phase metal and the size of the matrix phase--the tungsten carbide powder particle. The different binder content and the corresponding tungsten carbide particle size form different carbide grades. If the content of the metal binder is increased or the particle size of the tungsten carbide is increased, the hardness of the cemented carbide decreases and the toughness increases. Tungsten Carbide (WC) is twice as strong as steel and is similar to corundum in hardness. Tungsten carbide rollers combine superior hardness with resistance to abrasion and wear and they are available in a wide range of sizes. They can also be milled according to the customer's specifications. It has advantage of high wear resistance, long life and high efficiency during the high-speed rolling.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.