Product Description

Tungsten carbide, abbreviated as WC or TC, also called cemented carbide, hardmetal or widia, is a metal matrix composite where tungsten carbide particles are the aggregate and metallic cobalt serves as the matrix. It is a non-oxidizing ceramic that can withstand high temperatures while maintaining a hardness comparable to corundum or sapphire.

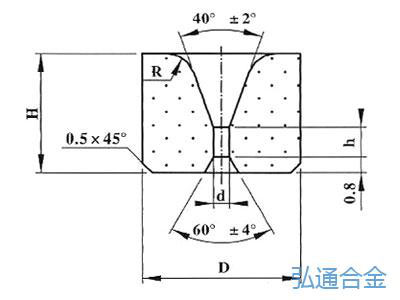

Advantage of Tungsten Carbide Dies

1. Material:100% virgin raw material with submicron grain size

2. Grade: Various grades for choice

3. Advanced production equipments and testing equipments

4. Precious Ground and polished

5. High wear resistance,high hardness and impact toughness

6. Advanced technology, automatic pressing, HIP sintering and precision grinding

7. Samples & small orders are acceptable.

| Grade No. |

Density (g/cm3) |

HRA |

T.R.S (Mpa) |

Application |

| YG3X | 14.9 | ≥91.5 | ≥1300 | For drawing non-ferrous metal wire and stainless-steel wire etc. |

| YG6 | 14.8 | ≥90.0 | ≥2150 | For drawing steel wire and stainless-steel wire etc. |

| YG6X | 14.8 | ≥92.0 | ≥1860 | For drawing nonferrous metal wire, steel wire, stainless steel wire. Good wear resistance and high toughness. |

| YG8 | 14.8 | ≥89.5 | ≥2320 | For drawing steel wire, stainless steel wire. Good general performance. |

| YG11 | 14.4 | ≥88.5 | ≥2420 |

For fabricating drawing dies of steel tubes and rods under high compressibility ratio; punching, stamping, forging tools under large stress. |

1. Tungsten carbide with high hardness, high wear resistance and high red hardness, at 550℃ still maintain more than 56HRC hardness.

2. Has a high modulus of elasticity, generally is (4~7)×104kg / mm2, and excellent rigidity at room temperature.

3. Have a high compressive strength which is greater than 6000MPa.

4. Have good resistance to oxidation and corrosion resistance, acid resistance, alkali resistance and high temperature not easily oxidized.

5. Has a low coefficient of thermal expansion, suitable for manufacturing high, precision, sharp die.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.