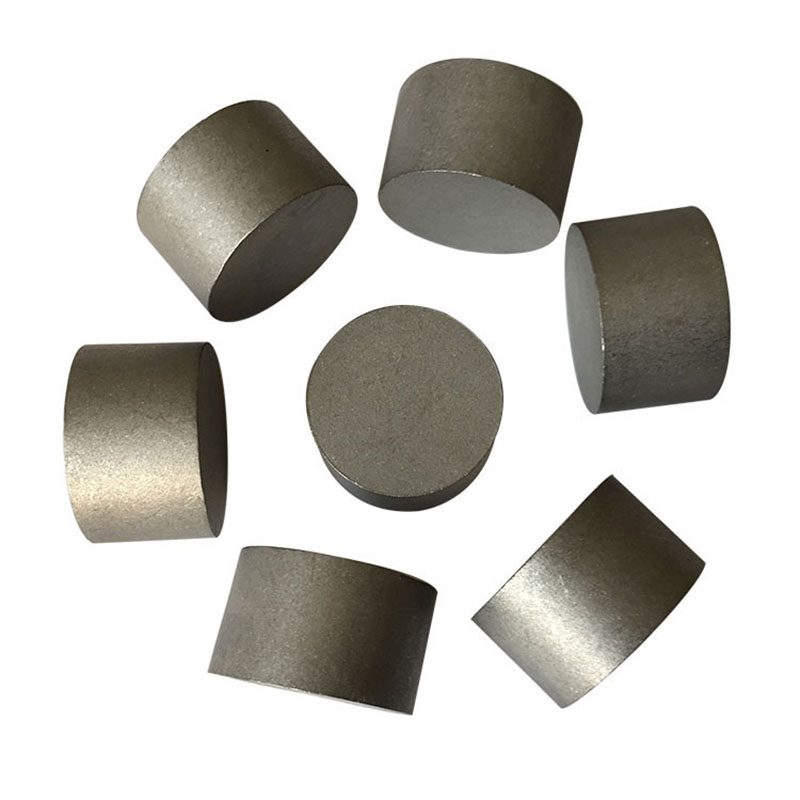

Polycrystalline diamond (PCD) is very hard, even harder than tungsten carbide. So there’re polycrystalline diamond cutter (PDC), which use a tungsten carbide substrate and layer of PCD coated. This structure can adapt the strength of carbide and hardness of diamond both, so the working life is much longer than others.

| SPEC SHEET--OIL & GAS DRILLING PDC CUTTERS | |||||

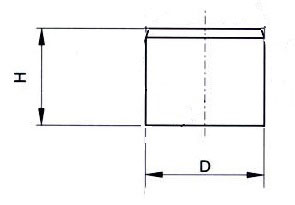

| Dimension Code | Diameter (ØD)mm | Height Total (H)mm | Diamond Height (mm) | Diamond Chamfer (mm) | Carbide Chamfer (mm) |

| 1919 | 19.05±0.05 | 19.0±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 1916 | 19.05±0.05 | 16.0±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 1913 | 19.05±0.05 | 13.2±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 1616 | 15.88±0.05 | 16.0±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 1613 | 15.88±0.05 | 13.2±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 1608 | 15.88±0.05 | 8.0±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 1313 | 13.44±0.05 | 13.2±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 1308 | 13.44±0.05 | 8.0±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 1008 | 10.00±0.05 | 8.0±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| 808 | 8.00±0.05 | 8.0±0.10 | 2.0-2.5 | 0.5x45° | 0.5x45° |

| Customized specifications Upon Request | |||||

| SPEC SHEET--COAL MINING PDC CUTTERS | |||||

| Dimension Code | Diameter (ØD)mm | Height Total (H)mm | Diamond Height (mm) | Diamond Chamfer (mm) | Carbide Chamfer (mm) |

| 1308 | 13.44±0.05 | 8.0±0.10 | 2.0±0.2 | 0.3x45° | 0.5x45° |

| 1304 | 13.44±0.05 | 4.5±0.10 | 2.0±0.2 | 0.3x45° | 0.5x45° |

| 1008 | 10.00±0.05 | 8.0±0.10 | 2.0±0.2 | 0.3x45° | 0.5x45° |

| 1004 | 10.00±0.05 | 4.5±0.10 | 2.0±0.2 | 0.3x45° | 0.5x45° |

| 0808 | 8.00±0.05 | 8.0±0.10 | 2.0±0.2 | 0.3x45° | 0.5x45° |

| 0804 | 8.00±0.05 | 4.5±0.10 | 2.0±0.2 | 0.3x45° | 0.5x45° |

| Customized specifications Upon Request | |||||

| Grade | Main Chemical (%) | Hardness (≥HRA) | Density (g/cm³) | T.R.S (≥N/mm²) | ||||

| WC | Co | Ni | Tic | Other | ||||

| YWN6 | 94 | - | 6 | - | - | 89 | 14.5-14.9 | 1500 |

| YWN8 | 92 | - | 8 | - | - | 88 | 14.4-14.8 | 1650 |

| YWN10 | 90 | - | 10 | - | - | 87 | 14.5-14.9 | 2100 |

| YG6 | 94 | 6 | - | - | - | 89.5 | 14.7-15.1 | 1550 |

| YG8 | 92 | 8 | - | - | - | 89 | 14.6-14.9 | 1850 |

| YG13 | 87 | 13 | - | - | - | 88 | 13.9-14.2 | 2400 |

| YG15 | 85 | 15 | - | - | - | 87 | 13.9-14.2 | 2500 |

Widely used in the cutting tools.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.